Edge compressive strength (CCT) of corrugated base paper

The Edge Compression Strength (CCT) of Corrugated Base Paper Corrugated cardboard boxes are made of corrugated cardboard. From the structural analysis of corrugated cardboard, it is composed of inner paper, surface paper, corrugated paper, and middle paper. Corrugated paper acts as a support like bone, and its impact on strength exceeds that of surface paper and inner paper. Therefore, the CCT test of corrugated base paper has become very important, and CCT mainly affects the compressive performance of corrugated cardboard boxes.

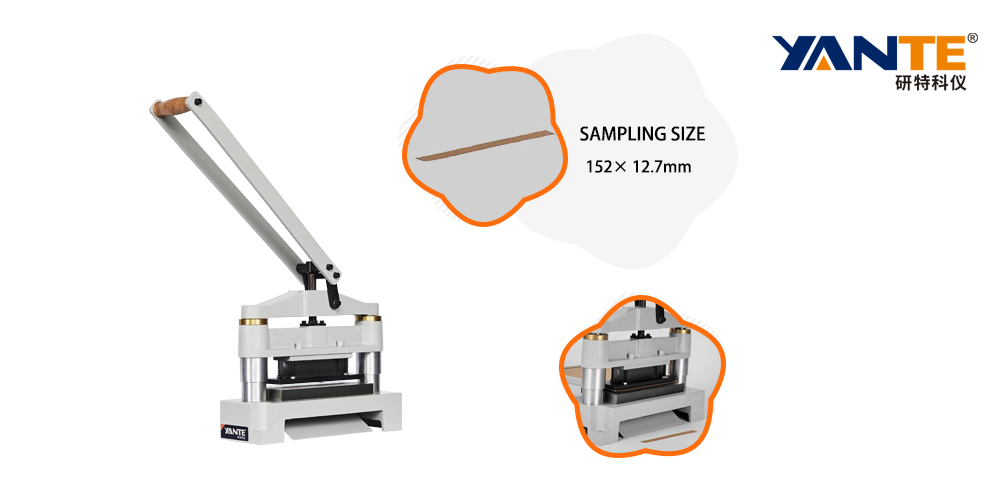

In order to further improve the accuracy of edge compression strength testing for corrugated paper, YANTE has independently developed a matching ring pressure sampler and a sample making instrument, the Concora Medium Fluter.

1、Edge compressive strength (CCT) test of corrugated base paper

Principle of edge compression strength testing for corrugated base paper: A certain size sample (152mm) × After corrugating on a groove tester with a diameter of 12.7mm, fix the specimen with a specimen holder and place it on a compression tester for compression testing. The maximum pressure that can be borne per unit length before the corrugation is crushed is measured in kilonewtons per meter (kN/m).

Experimental equipment and materials

Compression strength tester, ring pressure sampler, groove tester, CCT gripper, and corrugated base paper.

Experimental process

1. Sample collection and processing

Take and treat samples according to national standards GB/T 450 and GB/T 10739.

2. Sampling

Accurately cut a sample with a width of 12.7mm ± 0.1mm and a length of 152mm ± 0.5mm using a ring pressure sampler. There should be at least 10 samples, with the long side being the longitudinal direction of the sample. The parallelism of the long side of the sample should be within 0.01mm, and it should be clean and defect free.

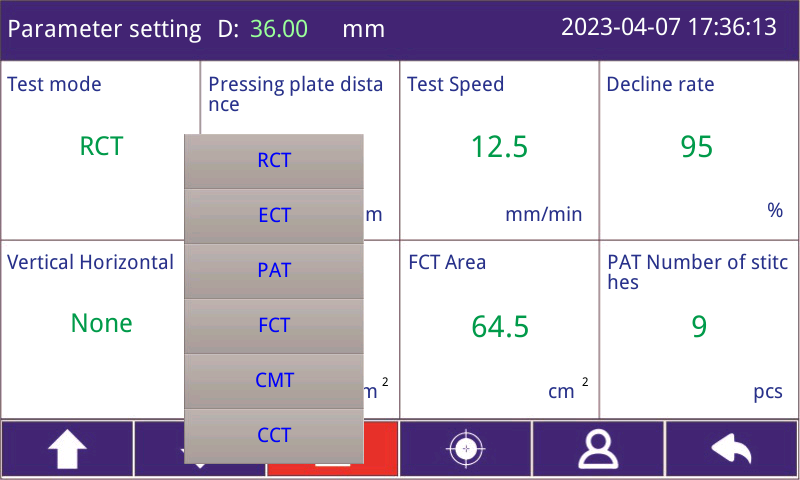

Parameter settings

Now switch the testing mode to CCT mode, set the testing speed to 12.5mm/min, and set the spacing between the pressure plates (slightly higher than the height of the sample by 12.7mm, such as 14-15mm), waiting for testing.

4. Corrugation sample preparation

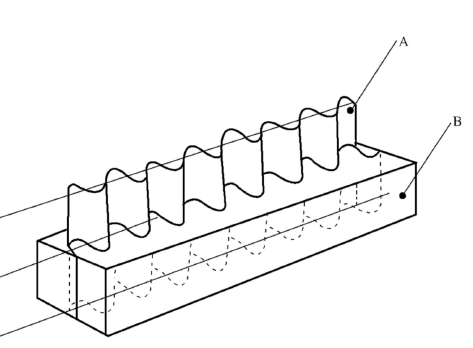

Start the groove tester. When the pressure roller is heated to (175 ± 8) ℃, insert the long side of the sample vertically into the feeding port to make the sample corrugated. Place the corrugated sample in the clamp.

5. Testing

There are two types of testing: testing immediately after corrugation and testing after 30 minutes of temperature and humidity treatment.

A-test sample B-gripper

Test immediately after corrugation. If the sample undergoes compression testing immediately after being corrugated, the time from corrugated to applying pressure should be within 20-25 seconds, which means that the sample should be tested immediately after preparation, i.e. CCT0.

5.2 Test after 30 minutes of temperature and humidity treatment. If the sample is subjected to temperature and humidity treatment after being corrugated, it should be treated in an environment with a temperature of (23 ± 1) ℃ and a relative humidity of (50 ± 2)% for 30-35 minutes, which is CCT30.

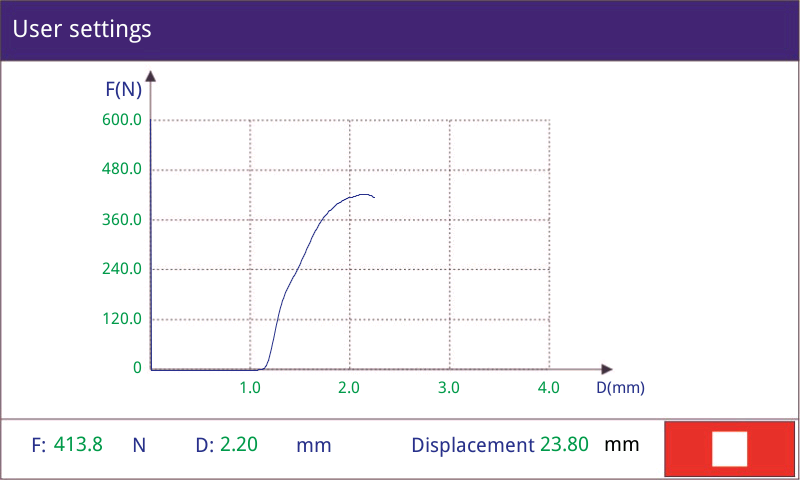

6. Result calculation

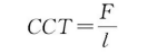

6.1 Edge compression strength of corrugated base paper

Calculate the edge compression strength CCT of corrugated paper according to equation (1), and the result is accurate to 0.01kN/m.

In the formula:

CCT - Edge compression strength, in kilonewtons per meter (kN/m);

F - Maximum pressure, unit: Newton (N);

L - The length of the sample before corrugation, in millimeters (mm).

In order to quickly confirm the method used for testing results, in most cases, the following result representation methods can be used:

CCT0=x.xx kN/m

CCT30=x.xx kN/m

Among them, CCT represents the edge pressure intensity, and the subscript represents the time for temperature and humidity treatment, in minutes.

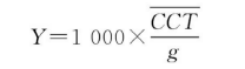

6.2 Edge compression strength index

Calculate the edge compression strength index Y of corrugated paper according to equation (2), in Newton meters per gram (N · m/g):

In the formula:

Y - Edge compression strength index, unit: Newton meters per gram (N · m/g);

- The average value of edge compression strength, in kilonewtons per meter (kN/m);

- The average value of edge compression strength, in kilonewtons per meter (kN/m);

G - Quantitative measurement of the sample, in grams per square meter (g/m2).